Imagine sitting at your desk in the office. Suddenly, you find yourself on a construction site – without physically being there. It sounds impossible, but for our customers dealing with firestop solutions, it’s already reality.

As a community engineer at Hilti Germany, Ralph Zeller organizes many virtual trainings for non-structural engineers. He is fond of their work: “As I walk into an office of engineers at any firm, I feel the sense of excitement and purpose with which they work. Various projects they are involved in, ranging from structural engineering to mechanical, electrical and civil engineering, become both an exciting journey and a sign of their engineering prowess,” he explains.

Non-structural engineers deal with all the complexities related to a building’s mechanical, electrical and plumbing (MEP) systems design. This may involve complex heating, ventilation and air conditioning (HVAC) ducts, a widespread electric cable network and intricate piping for the plumbing system. “The core task of non-structural engineers is to design the MEP services and make sure they are fit to supply the plumbing, electrical and HVAC needs of the building’s occupants and assets,” Ralph explains.

In dimensioning MEP systems, engineers realize their systems have to go through fire-rated walls and floors. Thus, if not designed properly, these systems could compromise the building’s fire integrity and even pose a danger to occupants. So, one of the challenges they face is designing for passive firestop solutions on top of all their other responsibilities. Proper MEP design includes not only piping, cables and their supports, but also correct passive firestop systems to seal penetrations in fire-rated walls and floors.

Ralph elaborates on some of the other problems to be solved: “Integrating firestop involves the consideration of various aspects – from local fire codes and regulations to the selection of the most suitable firestop solutions for specific applications, to coordination with electrical engineers, the HVAC team and plumbers, to the sync plans for cable penetrations, duct networks and pipes. Sometimes the project even demands custom firestop solutions, which bring additional unknown and unique challenges to the table.”

The new Firestop Engineering Training simply transforms the way engineers can comprehensively learn about firestop solutions while stepping into the real-life scenarios.

Ralph Zeller, Hilti Community Engineer in Germany

For engineers, it’s akin to solving a puzzle where every piece must fit perfectly. If the pieces don’t fit, this means a loss of time and money for the contractor, both during installation and at the inspection stage. “The overarching aim is to ensure that the MEP systems do not compromise the building’s fire-resistance integrity, that the work is done right the first time and that they stay within the budget,” adds Ralph.

To help ensure they keep the fire integrity of buildings, engineers spend a considerable amount of time learning about fire protection regulations and related product solutions. Traditional training methods can be time-consuming and classroom-based training usually leads to low engagement of the participants. This training also has the downside of not visualizing the impact that incorrect or unsuitable fire protection solutions can have in real-world fire scenarios.

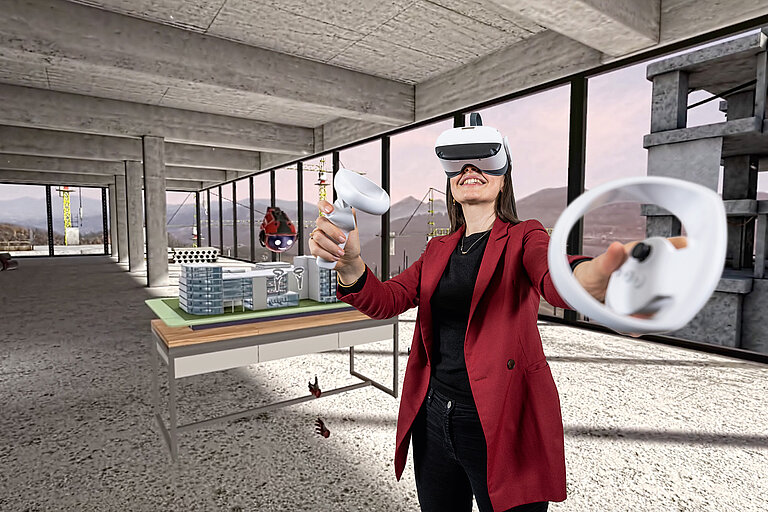

With Hilti’s introduction of the new Firestop Engineering Training, these gaps are now closing. With the help of virtual reality, Firestop Engineering Training offers an engaging and effective alternative for engineers to learn about firestop systems. “The new Firestop Engineering Training simply transforms the way engineers can comprehensively learn about firestop solutions while stepping into the real-life scenarios,” reiterates Ralph.

What makes the new Firestop Engineering Training unique

In-person virtual reality training, by Hilti experts, for MEP engineers and architects

The new Firestop Engineering Training is professional training for MEP engineers and architects who want to learn the latest regulations and practices of safely designing passive fire protection. It is conducted in person and in small groups, at the convenience of participants, by experienced Hilti trainers.

The realistic training environment boosts engagement. An engaging training session of approximately 3.5 hours incorporates usage of virtual reality headsets, where engineers can experience jobsite installation, fire simulations and six different design scenarios. The unique virtual reality environment developed especially for this training allows participants to handle objects, make choices and perform actions in a realistic environment. It increases retention and leads to better understanding and recall.

Blended learning with certification for local regulations

After participants complete the face-to-face training, they gain unlimited access to e-learning modules available from the Hilti Academy, where they can deepen their knowledge on specific topics and/or refresh what they have learned. Upon completion, all participants receive Hilti certification, which qualifies as continuous professional education according to their local regulations.

Hilti has always led the way as a pioneer by developing innovative solutions. Now, with Firestop Engineering Training and virtual reality, we help engineers perform their MEP designs productively and ensure their fire safety. We also give them a great customer and learning experience. Ultimately, the new Firestop Engineering Training makes construction better.

Quelle:

https://reports.hilti.group/2023/our-stories/firestop-meets-virtual-reality